You may have read about safety issues related to lithium-ion batteries lately - situations where the batteries have swelled or even caused a fire or an explosion. In the following, we briefly discuss what causes these safety issues and how they can be prevented.

All you need to know about safety in Li-ion batteries

1. Safety in lithium-ion (Li-ion) batteries

Li-ion batteries are lightweight, efficient, and have a high energy density compared to other batteries. Li-ion batteries are widely applied in diverse areas ranging from small appliances such as smartphones, tablets, laptops, and power tools to larger systems like electric and hybrid vehicles and energy storage systems. Critical to all these battery systems is a maximum level of safety.

2. What are the main components of a Li-ion battery?

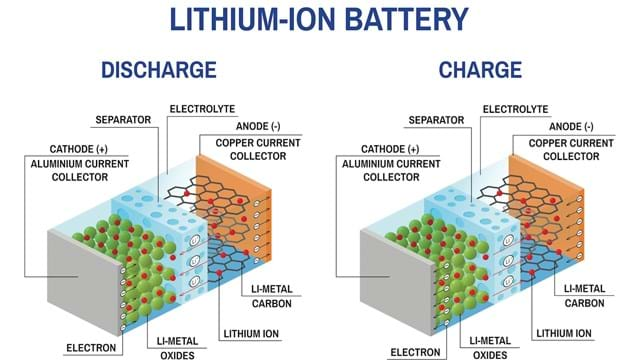

A Li-ion battery consists of four main components: a cathode, an anode, an electrolyte, and a separator.

- The cathode is the source of lithium ions.

- The anode stores and releases lithium ions from the cathode.

- The electrolyte medium allows the movement of the ions.

- The separator prevents contact between the cathode and the anode.

3. What are the safety issues of Li-ion batteries?

The main safety issue is related to the short circuiting of Li-ion batteries, which can lead to fire and explosion. The primary reason that Li-ion batteries short circuit is separator failure. When a separator fails and the two electrodes make contact, it can lead to a thermal runaway situation in which temperatures rise rapidly and cause the flammable liquid electrolyte to combust.

4. What is a battery separator?

The primary purpose of a separator in the battery is to act as an insulator between the two electrodes and prevent short circuiting. Although the separator is an insulator, it still needs to allow the transport of the ionic species between the electrodes. Ideally, a separator will be thermally, chemically, and mechanically stable. At the same time, it should have resistance to organic solvents, good wettability, and high puncture resistance, as well as being thin. Separators are typically microporous membranes (10-40µm) having a small pore size (<1µm) and low porosity (~40%). They are manufactured either by a dry or wet production process, including either an extrusion, or casting step, respectively.

5. Of what composition are Li-ion separators?

Typically, battery manufacturers use separators based on high strength polyolefin-based porous membranes such as polyethylene (PE) and polypropylene (PP). The challenges with these thermoplastic polymers are related to their temperature stability, as they soften at 130 °C and 165 °C, respectively. Battery producers utilise this softening as a safety feature since the collapse of the membrane pores prevents movement of ions through the membrane and leads to a shutdown of the battery. However, in some rare cases, such separator shrinkage may result in exposure of the electrodes, which leads to an internal short circuit. In a worst-case scenario, a fire or explosion of the battery will occur.

6. How to increase the safety of battery separators?

To meet the safety demands of Li-ion batteries, a focus of the industry has been to increase the temperature stability of separators. Several different routes for increasing the heat stability of separators for lithium-ion batteries have been considered:

- Ceramic coating: Ceramic particles with polymer binder are applied on one or both sides of the separator, resulting in reduced shrinkage, and at the same time increasing resistance and thickness.

- Ceramic reinforcement: Ceramic particles are added to the separator leading to reduced shrinkage and increased thermal stability.

- Polyimide blend nanofibres: Electrospun polyimide blend nanofibres offer high-temperature stability with very high porosity.

- Cellulose nanofibrils (CNFs) and Microfibrillated cellulose (MFC) have low conductivity, high chemical and pH stability, insolubility in common organic solvents and great film-strength, as well as low thermal shrinkage. They can be used as such, or incorporated into the separator matrix.