Exilva in January issue of International Paper Board Industry magazine

By showing great benefits to starch adhesives in the corrugated board industry, an article about Exilva has been included in the January issue of the International Paper Board Industry (IPBI) magazine. Key benefits are enhanced bonding effects, increased speed on complex qualities and warp improvement. Read the full article here.

Update: This article was also published in the March issue of Corrugated Today.

The special combination of robustness and rheological properties is what makes Exilva novel and well suited to users who are looking to upgrade their current corrugating adhesive solutions. The key benefits enables interesting productivity gains.

Exilva is a natural, radical technology and product innovation – and now it is available for corrugators. What does this mean for corrugator plants? In this article, we describe the Exilva technology with technical illustrations, including Exilva in combination with starch.

Figure 1. Exilva microfibrillated cellulose from Borregaard.

Various measurements explain some of the reasoning behind the positive results that have been experienced during the production of corrugated board, when working with current adhesive solutions.

Exilva is made by a new fibrillation technology of Norway Spruce, creating a three-dimensional network of flexible fibril aggregates with diameters of a few microns to a few hundred microns.

What is Exilva?

The name Exilva is from the Latin words ‘Ex Silva’, meaning ‘from the forest’. In fact, Exilva is made by a new fibrillation technology of Norwegian spruce, creating three dimensional networks of flexible fibril aggregates with diameters of a few microns to a few hundred microns (Figure 2).

Figure 2. Flexible cellulose microfibrils aggregates in a three-dimensional network.

The single microfibrils have a high aspect ratio and surface area and mainly consist of cellulose which has a lot of hydroxyl (OH) groups. These OH groups form strong hydrogen bonds with the surroundings. Being able to react both chemically and physically, Exilva can control the rheological properties in a formulation by increasing the viscosity, the shear thinning and yield stress behaviour. This results in improved storage stability and application properties.

The fibrils network of Exilva is extremely robust and can withstand harsh conditions such as extreme pH (1-13), temperature and shear forces.

How Does it Perform?

In a corrugating adhesive, the starch is present in many forms – gelatinised (water soluble), swollen (partly water soluble) and in granules (non-soluble). In the Stein-Hall process, as an example, gelatinised (cooked) starch constitutes about 15–17% of the total starch and is used to make a suitable formulation for the uncooked starch. Upon the addition of Exilva to the glue, the highly entangled network of cellulose fibrils enables a strong interaction with starch by multiple hydrogen bonding.

This three-dimensional network formation seems to stabilize the cooked starch towards retrogradation and furthermore, helps to stabilize the uncooked starch granules preventing them from sedimentation and possibly restrain the swelling.

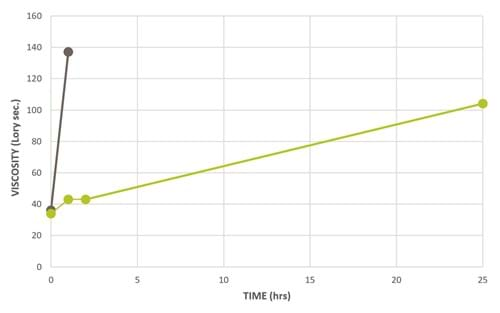

The improved storage stability of a Minocar starch adhesive comprising 1% Exilva compared to the same without Exilva, is shown in Figure 3. For both glues, the viscosity was measured initially and over time, under laboratory conditions (without stirring) at 20°C. The viscosity of the reference adhesive increased to critical level (137 Lory sec) after one hour.

Figure 3. Change in viscosity over time with Exilva added (green) in the adhesive against the reference without Exilva (brown).

In comparison, the viscosity of the adhesive with Exilva was only 43 Lory sec after one hour – and still below critical level after 25 hours of storage at 20°C.

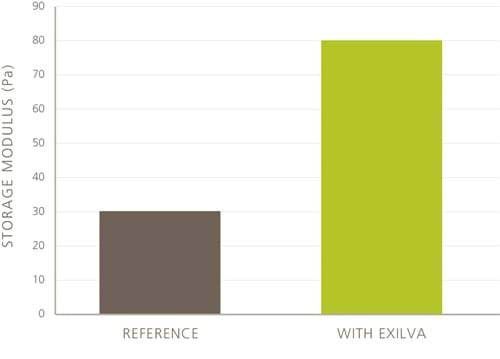

Furthermore, the storage modulus of the starch adhesive comprising Exilva (Figure 4, green bar) was much higher than for the reference adhesive without Exilva (Figure 4, brown bar).

Figure 4. Storage modulus of a starch adhesive (brown) comprising Exilva (green).

A high storage modulus is directly related to the extent of crosslinking, meaning that the adhesive with Exilva cellulose fibrils has a higher degree of chemical structure (by hydrogen bindings). This means that the strength of the network is higher for the adhesive with Exilva and therefore indicates a greater ability to keep starch polymers and granules in suspension.

The storage modulus of the starch adhesive comprising Exilva was much higher than for the reference adhesive without Exilva.

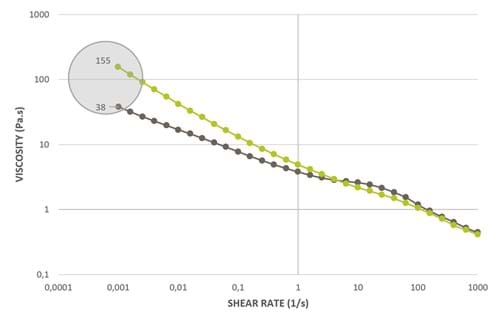

At a low shear rate, the addition of Exilva increases the viscosity of the glue, demonstrating the fibrils network formation which improves the glue stability. Upon increasing shear rate, the glue comprising Exilva is more shear-thinning, providing the similar viscosity during application (Figure 5).

Figure 5: The flow curves, showing viscosity as a function of shear rate, for a reference Stein-Hall

wheat starch glue (brown) and the similar glue with 0.8% Exilva (green).

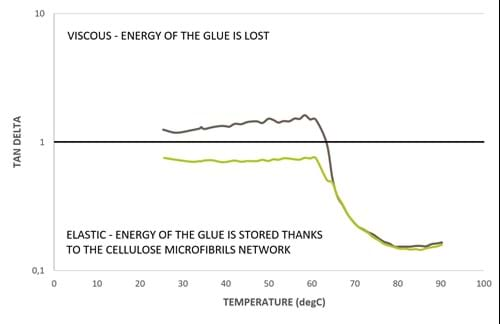

In Figure 6, the tan delta describing the viscoelastic behaviour of the glue and representing the portion of viscous and elastic character of the glue, is shown as function of temperature. The glue comprising Exilva (blue) shows a stable elastic behaviour over a broad range of temperatures, meaning that the network is not affected by the change in temperature before the glue is cured. The reference glue, a Stein Hall native wheat glue, shows a liquid behaviour before it is cured.

The solid characteristic of the Exilva cellulose fibrils increases the elasticity of the glue, which increases its ability and the strength of the final cured glue bond; measured as an increase in PAT (N/m) of +194% (Pin Adhesion Test on Double Backer of B-flute quality 115EK/100WF/115EK). In production, this effect of Exilva also seems to increase the opening time in a corrugating glue, like when potato starch is used, so it can overcome the forces of the slitter knives.

Figure 6: The viscous and elastic character as a function of temperature, with Exilva 0.8% added (green) versus the reference (brown).

What Improvements are Seen?

Exilva can be used in all glue processes and with all kinds of starches including one bag mixes (OBM). However, any potential improvement must be documented by running Exilva trials measured against its benchmark, as every corrugator is quite different.

Several factory trials (wheat, corn, Stein-Hall, Minocar) has proved that Exilva on top of current glue enables higher speed on all heavy qualities that have been tested. These qualities had glue as a bottleneck for speed. Until now, Exilva glue allowed users to increase speed until another bottleneck came up (for example, take off from the stacker or the order length). To verify, 0.8% Exilva was added to the existing recipe in the primary part (before primary starch or after caustic soda/the swelling of the starch). To get to the same viscosity, small adjustment can be done, for example in SteinHall, a little less carrier starch and in Minocar a bit higher kill viscosity can be used (Table 1, a Stein-Hall glue reference and recipe with Exilva).

[Contact us to see the example recipe for speed, productivity and quality with Exilva]

First, a benchmark of the existing recipe by optimizing the settings – like temperature, tension, glue gaps, is done by the operator for a well-known quality (e.g. 300K/150SC/150K/150SC/300K). After optimizing the current recipe, Exilva shall be added to measure the delta. So far, Exilva has given good results on speed increase, in the range of 10-45% increase on these complex qualities. Such cases should be tested and benchmarked individually, case by case.

The bonding and flatness seem to be more safe and provides control, comfort and convenience – for the operators and production management.

The bonding and flatness seem to be more safe and provides control, comfort and convenience – for the operators and production management. The productivity, both at the corrugator as well as through converting, has increased due to improved warp, better gluing and increased corrugator speed on the complex qualities. Less customer complaints as well as internal complaints from the converting department has been documented.

Want to try Exilva in your setup?

Order your free sample on this page, or contact Justin Scarpello directly at justin.scarpello@borregaard.com to schedule a plant trial. We will provide you with Exilva, guidance and on-site help.

You can find the International Paper Board Industry and more packaging news at The Packaging Portal.