Ion exchange resins

A manual ion exchange rig with two 40 L columns is available for testing of various ion exchange resins. Salts can be removed from a solution by first passing it through a cation-exchange resin to remove ions of alkali metals and alkaline earth metals. The acidic solution is then passed through an anion exchange resin to remove ions such as chloride or sulphate.

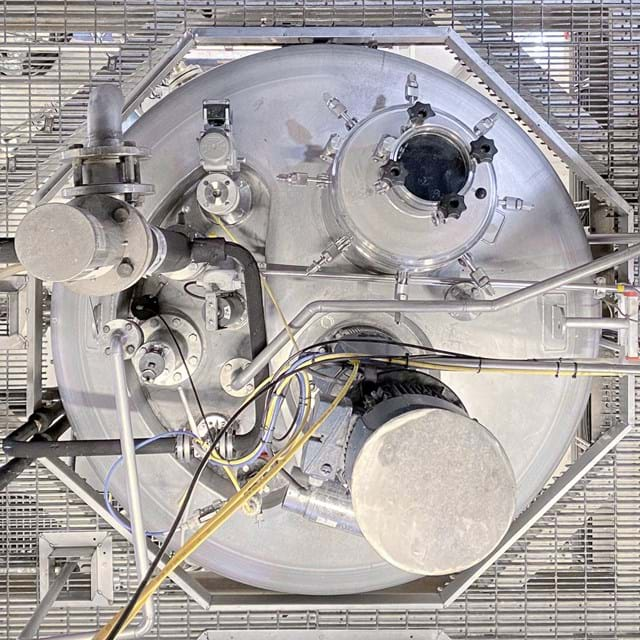

Evaporation

In a biorefinery, aqueous solutions can sometime be quite dilute. To concentrate these solutions, there are two options for removing water in Biorefinery Demo. There is one vacuum evaporator operating at 60-100°C and 80-950 mBar with a water removal capacity of up to 400 kg/h. The second option is a flash evaporator typically operated at 60-100°C and 40-950 mBar with a water removal capacity of up to 100 kg/h.

Storage tanks

There is a total tank storage capacity of 150 m3 in Biorefinery Demo, distributed over a multitude of tanks:

- 2 x 50 m3 pulp tanks with MC pumps

- 2 x 10 m3 storage tanks

- 2 x 8 m3 storage tanks

- 3 x 6 m3 storage tanks

The storage tanks are insulated and fitted with agitators, circulation pumps, temperature sensors, jacket heating/cooling and level sensors.

Flexible configuration

Initially, when an innovative process is taken from the laboratory to industrial scale, a number of scalable unit operations are selected for testing. The Biorefinery Demo is designed to be a flexible multi-purpose facility. The equipment and unit operations listed above can be easily configured in various sequences using flexible hoses. The selected unit operations are tested, and the settings are optimised. Then the first prototype batches of the innovative product are produced to test the quality and applications and enter the market before taking the financial risk of building a commercial-scale production line.

Laboratory

Biorefinery Demo services include process follow-up and preparation of samples for example by centrifugation and filtration. Samples can be prepared for storage and later analysis, for example the quantification of sugars, organic acids, or other intermediates or compounds of interest. Analytical capabilities in the Biorefinery Demo laboratory cover measurements of dry matter, pH, density, conductivity, refractive index, and optical density. The generated data can be used directly for feedback process control.

Operating staff

Equipment is useless without trained staff and we have an excellent team that ensures a quick and efficient scale-up. The team consists of 1 plant manager, 1 assistant plant manager and 3 operators who are all creative problem solvers with extensive technological know-how. The team has many years of experience and in-depth knowledge of the operation of many different types of process units. All operations are executed by members of the Biorefinery Demo team, to ensure solid documentation of trials. Samples are taken for process control as well as for advanced external analysis as required.