How to improve electrode properties and production process of Li-ion battery cells

How can a dispersant improve electrode properties of Li-ion batteries?

- Enabling increased solid content

- Impacting the density and thickness of the electrode coating

- Modifying the pore structure of the coating

- Increasing areal capacity

- Significantly reducing coating defects

Incorporating a dispersant into the formulation can enhance coin cell performance by optimising particle dispersion and reducing slurry viscosity. This leads to improved conductivity, increased areal capacity, and the ability to modify the density and pore structure of the electrode coating.

- Optimised particle distribution ensures a uniform and homogeneous distribution of active materials while providing long-term slurry stability. This improves the electrochemical conductivity and promotes better utilisation of the active material.

- Reduced slurry viscosity enables higher mass loading in the formulation, impacting the casting density and thickness of the electrode.

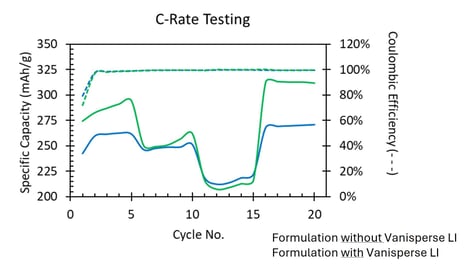

Coin cell cycling at different rates was conducted to assess the impact of Vanisperse LI’s on electrode performance. The testing demonstrated that Vanisperse LI improves life performance and enhances capacity retention at higher C-Rates, as shown in the figure to the right.

Cross-sectional SEM images of electrodes with improved capacity retention revealed that the dispersant Vanisperse LI not only reduces viscosity but also influences the pore structure and tortuosity of the cast layer.

Dose dependent changes in electrode tortuosity observable by SEM-imaging

Cross sectional SEM images of dry electrodes illustrates modified tortuosity and increased coating density with a dispersant. The leftmost image shows a control coating without Vanisperse LI, while subsequent images to the right show coatings with increased dosages of Vanisperse LI.

How dispersants contribute to the development of next-generation batteries

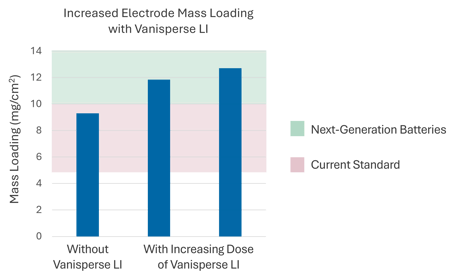

Dispersants play a crucial role in the innovation of next-generation batteries. Reaching even higher solid content is a key focus when developing advanced battery cells and optimising manufacturing efficiency. As demonstrated in the graph below, the standard mass loading for graphite electrodes ranges from 5-10 mg per cm2. By incorporating a dispersant like Vanisperse LI into the formulation, it is possible to achieve even higher levels of dry matter, reaching 10 mg/cm2 and beyond.

How can a dispersant improve the production process of Li-ion battery cells?

Dispersants effectively reduce the viscosity of the electrode slurry, which is essential for lowering costs and increasing throughput in battery cell manufacturing.

By reducing slurry viscosity, dispersants enable more flowable slurries with higher solid content and shorter drying times, significantly boosting in manufacturing efficiency. The dispersant also prevents particle jamming and improves flowability, further enhancing production performance. Combined with shorter slurry mixing times and reduced need for mechanical deagglomeration, these benefits result into substantial time and energy savings, as well as improved cost efficiency.

How to incorporate Vanisperse LI to your formulation?

The required dosage for optimal dispersion depends on the type of carbon, with surface area being one of the most significant factors. Download our bulletin for further technical details and dosage recommendations based on carbon surface area.

.png?width=517&height=128&name=Group%20(2).png)